Ultrasonic Cleaning

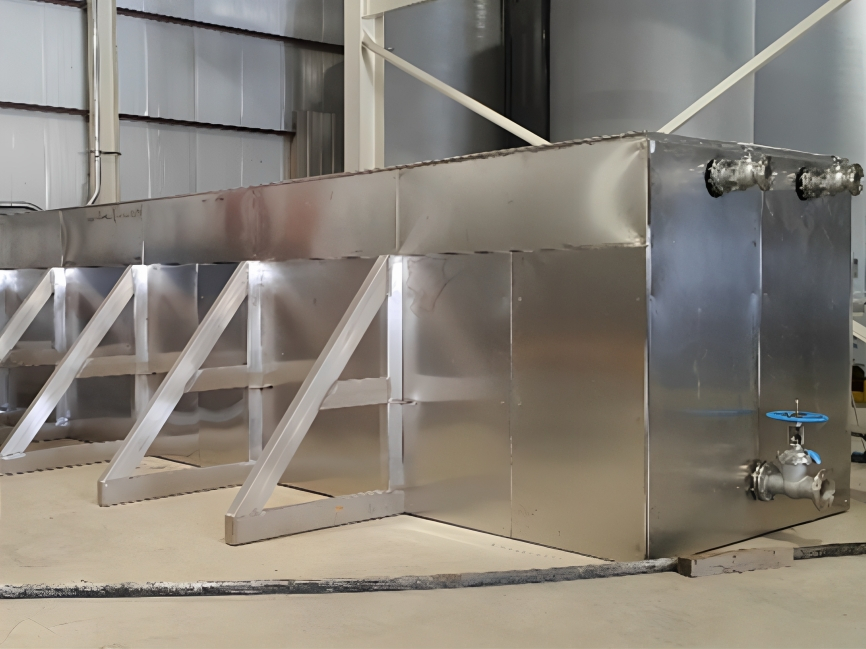

Exploring the benefits of ultrasonic cleaning industrial equipment

Ultrasonic cleaning is a powerful and efficient way to clean industrial equipment that’s difficult to clean using traditional methods. With ultrasonic cleaning, you can achieve better results in less time and with less effort.

Ultrasonic cleaning uses high frequency sound waves to create microscopic bubbles in a cleaning solution. These bubbles implode, releasing energy that removes dirt and contaminants from the surface of an object.

Ultrasonic cleaning is a simple and non-invasive process. The equipment is powered by electricity and requires only a cleaning solution and water input to get started. Items are placed in the cleaning solution and subjected to ultrasonic waves for a period of time.

Ultrasonic cleaning is one of the most efficient ways to clean industrial equipment, removing dirt and other contaminants quickly and effectively. Additionally, it is a gentle process that does not cause damage to the equipment.

Overview Of Ultrasonic Cleaning

Powerful Cleaning

Ultrasonic cleaning enables powerful and fast cleaning of industrial equipment with minimal effort.

Non-Destructive Cleaning

Ultrasonic cleaning is a gentle process that does not cause damage to equipment surfaces, extending equipment lifespan.

Environmentally friendly

Ultrasonic cleaning solutions are water-based and environmentally friendly, making them safer for the environment and equipment operators.

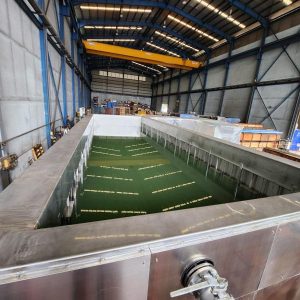

Before

After

Ultrasonic Clean

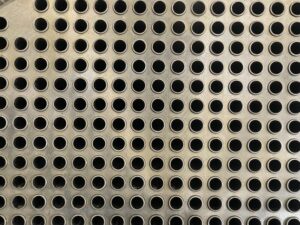

What do we clean with Ultrasonics?

- Spiral tube

- straight

- U-bend

- plate and frame

- etc

Advantages of Ultrasonic Cleaning

improved Efficiency and effectiveness

Ultrasonic cleaning can achieve cleaning results that other cleaning methods may not. The powerful sound waves penetrate the most challenging areas, ensuring an optimal cleaning process for industrial equipment, increasing efficiency and effectiveness of the cleaning process.

Increased Lifespan of equipment

By deeply cleaning the industrial equipment, ultrasonic cleaning ensures that parts are running optimally, as any built-up or remaining grime is removed. This ensures that the equipment lasts longer than usual, thereby reducing operating costs.

Cost Savings and Environmental benefits

Ultrasonic cleaning is a cost-effective method of cleaning industrial equipment. By utilizing less water and energy, ultrasonic cleaning is more environmentally friendly than other abrasive cleaning methods, thereby saving overall costs and helping make the planet a greener place.