Plant Construction

Services

overview

As a one-stop solution provider, we are able to undertake fabrication projects and site installations for our clients across South-East Asia. We also have the capabilities and expertise to efficiently undertake Greenfield & Brownfield projects ranging from construction of new industrial plants, modification & upgrade of existing plants. Additionally, our tankage team has strong capabilities in fabrication, construction, tank repair and maintenance

Integrated Fabrication

Introduction

We are equipped with in-house machinery and equipment including an automated pipe spool fabrication system and orbital welding machines to meet our clients’ requirements, we are able to spearhead production planning, material handling with approved drawings, maintain client requirements and ensure quality works that adheres to your timeline.

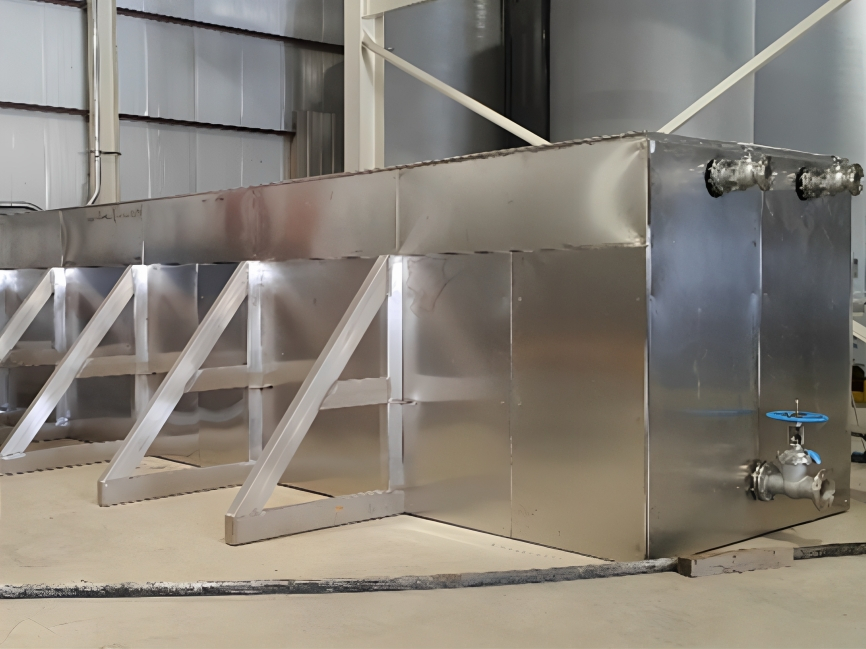

We can design, purchase materials and fabricate according to international standards such as ASME, TEMA, ASTM, API, NACE for stainless steel, carbon steel, mild steel, alloy, and other exotic materials.

Scopes of Services

Fabrication of Pressure Vessel/ Heat Exchangers and Air Fin Coolers

Fabrication and Erection of Steel Structures

Fabrication and Installation of Piping Works Including Blasting and Painting

Fabrication of Pre-Assembled Modules (PAM), Skids

Tankage Fabrication

Blasting and Painting

Quality Control

We conduct multiple quality control processes to ensure the highest level of quality in our all fabrication work.The following are some examples of QC processes we conduct in-house:

Welding Inspection

ITP, WPS/ PQR Preparation

PWHT

Hardness Testing

Positive Material Identification (PMI) Testing

Ultrasonic Testing (Thickness Measurement)

Ultrasonic Bolt Stress Measurement

Dye Penetrant Testing

Ferrite Count

Blasting & Painting Inspection (NACE)

Mechanical Run Testing, Hydrotesting and Recording

Holiday Testing (High-Voltage Spark Testing)

Holiday Testing (Low-Voltage Wet Sponge Testing)

Magnetic Particle Testing (MPT)

Laser Shaft Alignment for Rotating Equipment

Dry Film Thickness Painting Test

Phased Array Ultrasonic Testing (PAUT)

Munsiong's

Facilities

-

2 Fabrication Workshops: 3,683sqm

-

Open Yard: 9,339sqm

-

Overhead Cranes: 6 Units, 20T, 12.5m Height Clearance

-

Waterfront Length: 91.708m

-

Automated Pipe Spool Fabrication and Welding Workshop

– Carbon Steel : 300 ⌀”/shift

– Stainless Steel: 200 ⌀”/shift

Equipment

Plant Construction

We provide a complete range of construction and project works professionally carried out by our experienced teams. Backed by detailed planning, safety standards, operational reviews, and proper documentation, our teams are ready to manage various types of site conditions and meet your expectations.

Scope of Services

Design, Fabrication and Erection of Steel Structures/ Fixed Equipment

Design, Prefabrication & Installation of Piping Works

Installation of Static & Rotating Equipment

Design, Prefabrication of Pre-Assembled Modules (PAM), Skids

Construction Management of Plants & Refineries

Design, Site Installation of Electrical & Instrumentation Works

Tank Construction

Scaffolding

Gallery

Tank Construction, Maintenance & Rehabilitation

Our tankage team has strong capabilities in fabrication, construction, tank repair and maintenance.

New Tank Construction

We provide the full EPC of new tank construction on field with strong capabilities to undertake the construction of all types of tanks including spherical tanks & atmospheric tanks (cone roof/dome roof/floating roof tanks) following API 650 & API 620 standards.

In addition to the conventional field erection method, and as part of our unyielding commitment to achieve, quality, safety and work productivity, we have implemented mechanisation and automation in our tank fabrication and construction processes.

Welding Automation Equipment:

Automatic Vertical Up Seam Welding Machine

Automatic Horizontal Girth Seam Welding Machine

Automatic Butt/Corner Seam Welding Machine

Hydraulic Lifting System

TANK REHABILITATION and MAINTENANCE WORKS

Mun Siong has a strong track record in maintenance, rehabilitation, repair and reconstruction of Tanks, following API 653 standard.

Demolition & Reconstruction or Conversion of Tank Roof: Internal/ External Roof, Cone Roof, Dome Roof

External/Internal Jack-up for: Tank Bottom or Annular Plates Repair & Replacement

Installation of Tank Bottom Plate

Repair & Replacement of Floating Roof Drain System, Rolling Ladder

Repair or Replacement of Tank Internal Heating Coil, Sparger Pipe System, Water Draw-off Piping

Repair & Replacement of Tank Shell/Roof Nozzles, Manways, Venting Systems

Repair & Replacement of Fire Water/ Foam Pipe System

Other Rectification Works: Tank Shell Buckling

Hydro-Test & Handover

Scaffolding