Curran International

Overview

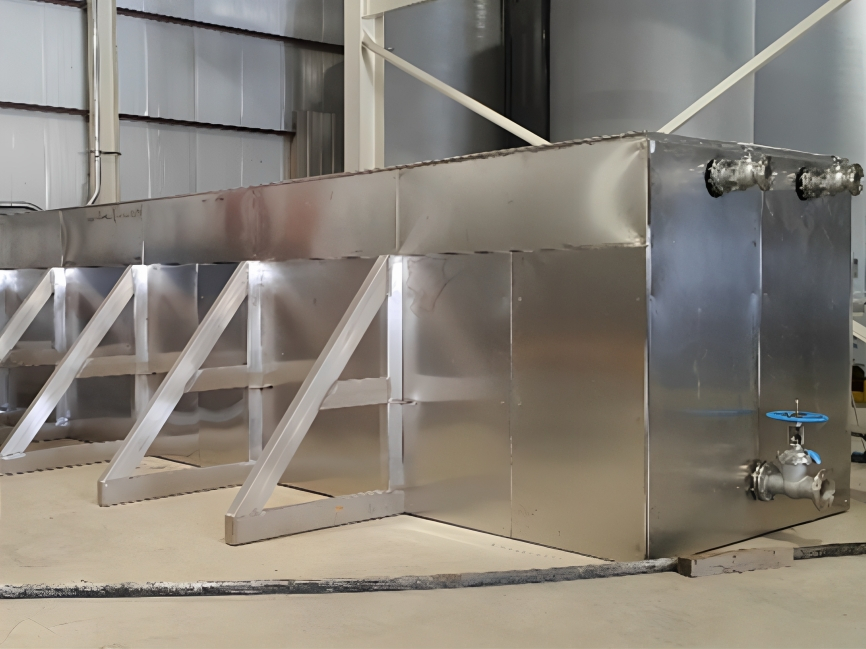

We are the sole distributor for Curran International in Singapore and Malaysia. Curran International provides innovative solutions to improve the reliability of fixed equipment. It is also recognised globally for its exchanger tube ID coatings that minimise tube fouling and inhibits corrosion. Curran International provides a wide range of Tubular Heat Transfer Equipment Services to restore exchangers and extend the useful service life of fixed assets.

Services

Industries

Oil & Gas

Petro - Chemical

Refinery

Power Generation

Nuclear Power

Pulp & Paper

Metal

Benefits

Protection of tube metal by polymer coatings will prevent oxide formation on your tube wall, extending life and eliminating unplanned maintenance of tube leaks. Coating can be used to protect against aggressive acid and alkaline.

Polymer coatings will reduce the surface tension of even a new tube by factor of 50; this inhibits the ability of fouling to attach to the tube wall, and eliminating cleaning cycles.

Over 70% of total heat transfer resistance for heat exchanger tubing is boundary layer fluid film and fouling. Removal of fouling and reduction of boundary layer drag of the exchanger enhances flow profile of the tube wall for the operational life, increasing heat transfer.

The sleek properties of high performance coatings substantially reduce tube wall friction, or boundary layer drag. Reducing drag can increase flow rates up to 80%, pressure differentials have been reduced by 50%. Without flow degration from corrosion and fouling these values remain constant.

Curran International

Exchanger Tube Id Coating

Thin-film exchanger coatings have proven to mitigate fouling and corrosion that reduces asset life and cause unplanned shutdowns. Fouling leads to reduced heat transfer and production bottlenecks, increased maintenance; tube corrosion risks the integrity of exchanger mechanical performance and plant safety.

Tube Id Coating

An advanced two part 100% solids epoxy coating designed for high temperature immersion service in cooling water, hydrocarbons and process streams. This coating is an organic/inorganic hybrid with prior mechanical performance; resistant in cooling water steam services to 365°F (185°C) and excursions to 400°F (204°C). Applied to 8-14 mils total DFT.

An ultra-low DFT ambient-cure coating system designed for high-temperature fouling services; possesses excellent hydrophobic & oleophobic properties, anti-coking performance, resistant to thermal cycling and is suitable for services to 1200°F (648°C). Ideally suited for heat exchanger tubes, plate & frame exchangers. Applied to 20-40 microns total DFT.

Shop applied, bake catalysed, suitable for all cooling water services, hydrocarbons, salt solutions and solvents. Immersion resistance to 365°F (185°C); applied to 7-10 mils total DFT.

Shop applied, bake catalysed thermo-melts; superior resistance in chemicals, solvents and acids. Immersion resistant to 500°F (260°C). Applied to 8-14 mils DFT.

A polymer surface treatment; omniphobic (water and oil repellant) nanocomposite surface treatment that creates a slick surface. Applied to 50 mils; water and product services to 400F (204°C).

Coating for Fixed Equipment

An advanced two-part 100% solids epoxy. It is a high build coating that can be applied by brush or roller in one coat to repair and protect steel surfaces in wet/ immersion environments while still providing excellent corrosion resistance.

Condenser and Chiller tube sheets

Water boxes

Channels

Circulating water piping

Temperature resistance 180°F (82°C) immersed.

Thermally cycled from 212°F to 32°F (100°C to 0°C) (20 cycles with no affect).

An advanced two-part 100% solids epoxy coating designed for high-temperature immersion service in cooling water, hydrocarbons and process streams. This coating is an organic/inorganic hybrid with prior mechanical performance; resistant in cooling water steam services to 365°F (185°C) and excursions to 400°F (204°C). Applied to 8-14 mils total DFT.

An advanced two-part (100% solids) epoxy coating designed specifically for high-temperature immersion service in water and process streams 365°F (185°C). This coating is an organic/ inorganic hybrid that exhibits the state of the art coating technology; it is formulated for high build sprayable applications, up to 40 mils in a single coat. Can withstand multiple cycling and steam out events subjected to process equipment.

Process vessels/ Tanks

Piping

Channels

Tube sheets

Waterboxes

Temperature resistance 365°F (185°C) immersed.

Tolerates excursions/steam outs to + 400°F (204°C).

A 100% solids hybrid novolac epoxy used to repair corroded steel, formulated to provide resistance in “cold wall” services, where coated substrate protects steel in hot immersion service and outer surface may be uninsulated. Atlas cell tested six-plus months de-ionised water at 210°F (98°C); pressurised Atlas Cell tested for 60 days de-ionised water at 365°F. When fully cured, Curran 1500 is machinable coating and can be used for flange repairs.

Suitable for:

Uninsulated Vessels & Pipe ID in Hot Immersion Service Channels, Bonnets, Restoration of Pitted Steel

Curran International

Exchanger Cleaning

Curran International’s patented dry grit blast tube ID cleaning process has revolutionised how clients clean their tubes in preparation for Non-Destructive Evaluation (NDE). Compared to conventional tube cleaning, Curran cleaning offers predictable results, eliminates cleaning rework, and promotes high integrity inspection data collection. Air coolers, shells & tube exchangers can be cleaned in situ; a dust abatement system ensures containments are vacuum-tight. Curran is experienced with process air coolers, SRU reactors, boilers and condensers, all metallurgies and U tube exchangers. Technicians visually confirm cleanliness, eliminating cleaning rework. Great Fill Factor for NDE Probes, Better Data Accuracy Reduced Background “Noise” Faster Technician Analysis Complete Waste Containment, No Nuisance Impact