Products

Overview

We are the sole distributor of Conco Systems in Singapore. Conco enables power plants, refineries and industrial production facilities to improve profitability, productivity and reliability through a uniquely integrated platform of products and services for condensers and heat exchangers.

Services

Industries

Refinery

Power Generation

Petro - Chemical

Nuclear Power

Food & Beverage

Marine

Benefits

When your plant is reliable and productive, efficient energy production is high and maintenance costs are low, improving your bottom line and increasing your profits.

Clean condenser and heat exchanger tubes lead to improved and more effective flow and heat transfer rates, increasing overall output. Clean tubes can increase efficiency by as much as 4%.

Impurities and leaks lead to unscheduled downtime. Regular tube inspection makes your plant more dependable, identifying equipment fatigue and corrosion before they cause forced unplanned outages.

Conco

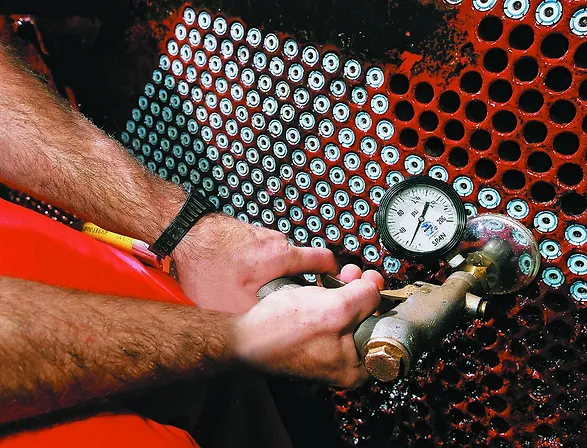

Tube Shooting

ProSeries 200B Tube Cleaning System with TruFit Tube Cleaners. This state-of-the-art equipment has effectively cleaned over 150 million condenser and heat exchanger tubes worldwide. Designed to shoot Conco TruFit or any other make or model of tube cleaners through tubes from 1/2” to 11/2” O.D. , it increases available water pressure up to 300 PSI necessary for effective cleaning. This unit is equipped with a 10 HP motor and a durable positive displacement two - gun pump.

Tube Cleaners

Each tube cleaner is designed for specific fouling types and sizes for your exact tube dimensions to ensure safe and effective tube cleaning.

Conco has more than a dozen designs engineered for the effective removal of fouling and underlying corrosion.

Conco

Rotary Drilling

Utilizing a water flush and rotary action, Conco HydroDrill Tube Cleaning Systems are the fastest and most effective way to remove difficult deposits from the inside of heat exchanger tubes, chemical reactors, condensers, reboilers and absorbers. The HydroDrill system is designed for maximum cleaning effectiveness with no tube damage. Drill bits are sized to be 0.005” below the minimum tube I.D. They feature long shanks to ensure that the axis of the bit and the axis of the tube are in complete alignment. Furthermore, the bits are designed with carbide tips on the leading edge with rounded corners to ensure no sharp edges directly impact the tube wall. The drill also rides on a thin layer of water for lubricating bearing surfaces between the bit and the tube. HydroDrills have been used repeatedly to clean process fouling on some heat exchangers over 1,000 times – with no tube damage or degradation. HydroDrills are used to remove hard tough deposits including: Coke, Calcium, Sulfur, Bauxite, Alumina, Asphalt, Oxides, Polymers

Conco

Inserts

Alkaserts® Polyethylene Tube Inserts Alkaserts are designed to ensure lasting protection to the inlet ends of new tubes and to greatly prolong the life of worn tubes damaged by erosion and impingement. Features: Bonnet head is designed to cover the ferrule in ferrule type installations. Flush head is used for flush, rolled-in tubes and close-clearance tubesheet designs.

Tube Plugs

Our inventory includes High Confidence Tube Plugs, tested to over 1,000 PSI under a wide range of temperatures and vibration conditions. Our line of expanding tube plugs can be used for temporary or permanent plugging. While our EX-3 Expanding Tube Plugs feature an oversized washer to prevent them from being pulled into the tube by the vacuum of the unit, our EX-4 Tube Plugs are designed to be placed inside the tube, recessed just below the tube sheet. Then there are our EX-F Tube Plugs, offering two separate gripping and sealing designs in one plug and sealing to 400 PSI. Type-1 Pin and Type-2 Pin and Collar Tube Plugs come standard in titanium, stainless steel, brass and bronze. They seal at high temperatures, allowing continued use of the unit without a major overhaul. They are ideal for use in the tube sheet where tube samples have been extracted.

When you need to plug off leaking tubes in condensers and heat exchangers, look no further than Conco. Conco offers a full range of plug sizes, styles and materials to match your needs.

Overview

We are the sole distributor for Curran International in Singapore and Malaysia. Curran International provides innovative solutions to improve the reliability of fixed equipment. It is also recognised globally for its exchanger tube ID coatings that minimise tube fouling and inhibits corrosion. Curran International provides a wide range of Tubular Heat Transfer Equipment Services to restore exchangers and extend the useful service life of fixed assets.

Services

Industries

Oil & Gas

Petro - Chemical

Refinery

Power Generation

Nuclear Power

Pulp & Paper

Metal

Benefits

Protection of tube metal by polymer coatings will prevent oxide formation on your tube wall, extending life and eliminating unplanned maintenance of tube leaks. Coating can be used to protect against aggressive acid and alkaline.

Polymer coatings will reduce the surface tension of even a new tube by factor of 50; this inhibits the ability of fouling to attach to the tube wall, and eliminating cleaning cycles.

Over 70% of total heat transfer resistance for heat exchanger tubing is boundary layer fluid film and fouling. Removal of fouling and reduction of boundary layer drag of the exchanger enhances flow profile of the tube wall for the operational life, increasing heat transfer.

The sleek properties of high performance coatings substantially reduce tube wall friction, or boundary layer drag. Reducing drag can increase flow rates up to 80%, pressure differentials have been reduced by 50%. Without flow degration from corrosion and fouling these values remain constant.

Curran International

Exchanger Tube Id Coating

Thin-film exchanger coatings have proven to mitigate fouling and corrosion that reduces asset life and cause unplanned shutdowns. Fouling leads to reduced heat transfer and production bottlenecks, increased maintenance; tube corrosion risks the integrity of exchanger mechanical performance and plant safety.

Tube Id Coating

An advanced two part 100% solids epoxy coating designed for high temperature immersion service in cooling water, hydrocarbons and process streams. This coating is an organic/inorganic hybrid with prior mechanical performance; resistant in cooling water steam services to 365°F (185°C) and excursions to 400°F (204°C). Applied to 8-14 mils total DFT.

An ultra-low DFT ambient-cure coating system designed for high-temperature fouling services; possesses excellent hydrophobic & oleophobic properties, anti-coking performance, resistant to thermal cycling and is suitable for services to 1200°F (648°C). Ideally suited for heat exchanger tubes, plate & frame exchangers. Applied to 20-40 microns total DFT.

Shop applied, bake catalysed, suitable for all cooling water services, hydrocarbons, salt solutions and solvents. Immersion resistance to 365°F (185°C); applied to 7-10 mils total DFT.

Shop applied, bake catalysed thermo-melts; superior resistance in chemicals, solvents and acids. Immersion resistant to 500°F (260°C). Applied to 8-14 mils DFT.

A polymer surface treatment; omniphobic (water and oil repellant) nanocomposite surface treatment that creates a slick surface. Applied to 50 mils; water and product services to 400F (204°C).

Coating for Fixed Equipment

An advanced two-part 100% solids epoxy. It is a high build coating that can be applied by brush or roller in one coat to repair and protect steel surfaces in wet/ immersion environments while still providing excellent corrosion resistance.

Condenser and Chiller tube sheets

Water boxes

Channels

Circulating water piping

Temperature resistance 180°F (82°C) immersed.

Thermally cycled from 212°F to 32°F (100°C to 0°C) (20 cycles with no affect).

An advanced two-part 100% solids epoxy coating designed for high-temperature immersion service in cooling water, hydrocarbons and process streams. This coating is an organic/inorganic hybrid with prior mechanical performance; resistant in cooling water steam services to 365°F (185°C) and excursions to 400°F (204°C). Applied to 8-14 mils total DFT.

An advanced two-part (100% solids) epoxy coating designed specifically for high-temperature immersion service in water and process streams 365°F (185°C). This coating is an organic/ inorganic hybrid that exhibits the state of the art coating technology; it is formulated for high build sprayable applications, up to 40 mils in a single coat. Can withstand multiple cycling and steam out events subjected to process equipment.

Process vessels/ Tanks

Piping

Channels

Tube sheets

Waterboxes

Temperature resistance 365°F (185°C) immersed.

Tolerates excursions/steam outs to + 400°F (204°C).

A 100% solids hybrid novolac epoxy used to repair corroded steel, formulated to provide resistance in “cold wall” services, where coated substrate protects steel in hot immersion service and outer surface may be uninsulated. Atlas cell tested six-plus months de-ionised water at 210°F (98°C); pressurised Atlas Cell tested for 60 days de-ionised water at 365°F. When fully cured, Curran 1500 is machinable coating and can be used for flange repairs.

Suitable for:

Uninsulated Vessels & Pipe ID in Hot Immersion Service Channels, Bonnets, Restoration of Pitted Steel

Curran International

Exchanger Cleaning

Curran International’s patented dry grit blast tube ID cleaning process has revolutionised how clients clean their tubes in preparation for Non-Destructive Evaluation (NDE). Compared to conventional tube cleaning, Curran cleaning offers predictable results, eliminates cleaning rework, and promotes high integrity inspection data collection. Air coolers, shells & tube exchangers can be cleaned in situ; a dust abatement system ensures containments are vacuum-tight. Curran is experienced with process air coolers, SRU reactors, boilers and condensers, all metallurgies and U tube exchangers. Technicians visually confirm cleanliness, eliminating cleaning rework. Great Fill Factor for NDE Probes, Better Data Accuracy Reduced Background “Noise” Faster Technician Analysis Complete Waste Containment, No Nuisance Impact

Overview

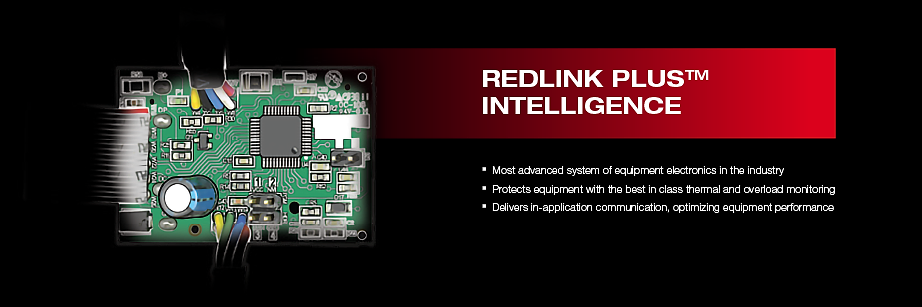

Milwaukee Tool is an industry-leading manufacturer of heavy-duty power tools, accessories, hand tools, storage and PPE for professional users worldwide.

Milwaukee

M12 Cordless Tools

The MILWAUKEE™ M12™ cordless system delivers industry-leading durability and power in a compact size that outperforms in the tightest places. M12™ defines cordless tool innovation, transforming inefficient manual tools such as cable and copper tubing cutters into advanced workhorses powered by MILWAUKEE™’s REDLITHIUM™ battery technology More than 100 unique solutions make the M12™ family one of the largest sub-compact cordless systems on the market.

Milwaukee

M18 Cordless System

The MILWAUKEE™ M18™ cordless system represents the ultimate synergy of professional-grade power, lightweight, extreme performance and superior ergonomics. These tools come with patented technologies, innovative motors and advanced electronics powered by REDLITHIUM™ battery technology for unmatched run-time at the job site. Offering more than 200 unique solutions, the M18™ family is the fastest growing 18V cordless system on the market.

Milwaukee Products Enquiry

For Milwaukee products enquiries, please call: +65 9810 0797 or fill out the following form below:

overview

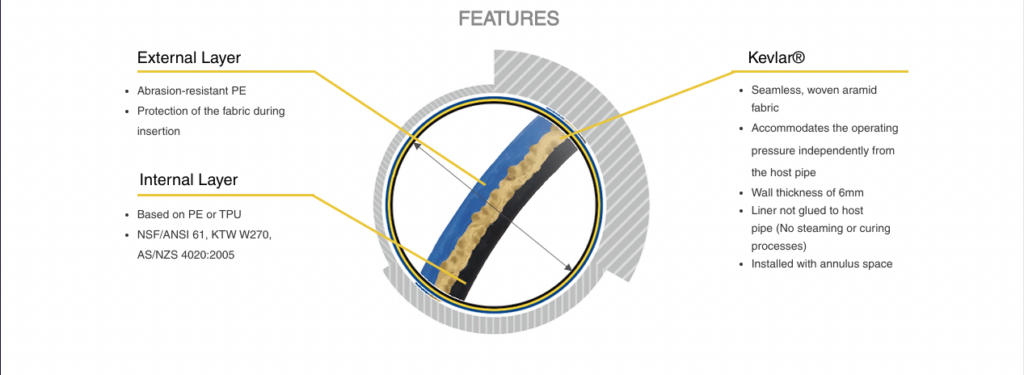

We are an authorised Prime Installer for Primus Line® in Singapore. Primus Line® is an innovative technology for the trenchless rehabilitation of pressure pipelines for different media such as oil, water and gas.

The Prime Solutions for Pipes

The system consists of a Flexible Kevlar® reinforced liner and specially developed end fittings. Primus Line® is not bonded to the host pipe.

Suitable Applications

The industry is facing new challenges as a result of damage to steel pipelines caused by internal corrosion. Possible leakages might cause significant environmental damage; they also mean increased costs or even loss of reputation for network operators.

Primius Line

Water

Primus Line® is suitable for the transportation of various liquids in the field of water and holds drinking water approvals in numerous countries. The ideal flow characteristics caused by an extremely smooth inner coating and optimised systems for high, medium, and low-pressure requirements make Primus Line® an economical solution for the rehabilitation of ageing pipelines. Thus, water authorities and network operators benefit from the reliable operation and sustainable investment in their fixed assets. Potable Water, Firefighting Water, Industrial Water, Sea Water, Waste Water

Primius Line

Oil

Primus Line® is suitable for the renovation of oil pipelines due to the medium-specific inner layer and acts as a corrosion barrier between the transported fluid and host pipe. The conveyed fluid covers media from the categories such as crude oils, fuel oils, oil slag and other refined products. Gathering Pipelines, Transmission Lines , Jetty Pipelines, Process Water Mains, Fire Fighting Mains. Please get in touch with us for our Chemical Resistance sheet to know more.

Primius Line

Gas

Gaseous media represents a special challenge to trenchless pipeline rehabilitation. However, an inner layer made of permeation reducing plastics and the seamless production of up to 4,500 metres (14,763 feet) of the Primus Line® pipe has made it possible for gas pipelines to also be renovated with Primus Line®. A monitoring pipe with a fitted valve that is affixed to the old pipeline allows the system-specific annular space to be monitored after the renovation work. Natural Gas Core Gas Liquid Gas Mixed Gas. Please get in touch with us for our Chemical Resistance sheet to know more.

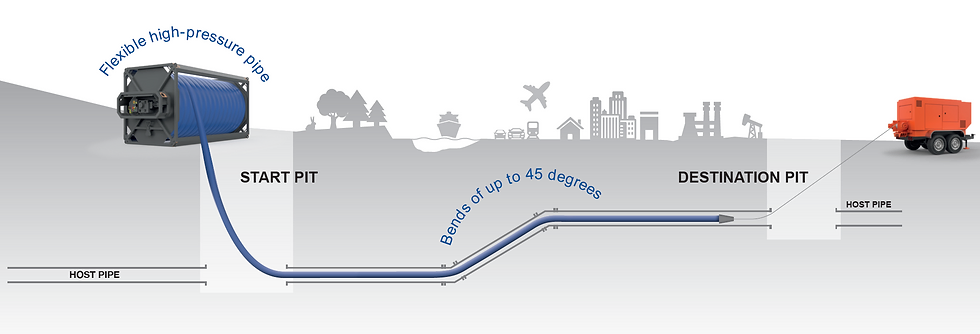

Installation

1. INSTALLATION OF THE LINER

Assembly of the pulling head

Before installation, the liner is fitted with a pulling head that is designed for forces of up to 100 kN. A swivel in the pulling connection with the winches prevents the liner from twisting on its way from the start to end pit.

Installation

The liner is delivered folded. That way Primus Line® can be installed even in pipes with the same nominal diameter.

Adhesive tape keeps the liner in this U-shape until it is pressurised with about 500 mbar. Subsequently, it assumes its round form.

2. ASSEMBLY OF THE CONNECTORS

Assembly of the M-Connector

The M-Connectors by Primus Line consist of a bushing and a core. With the M-Connector, a pull-proof unit out of the liner and connector is established by hydraulically pressing the core into the bushing.

Screwed to a flange on the host pipe a leak-free pull-proof connection is established that forms a closed annulus.

Assembly of the R-Connector

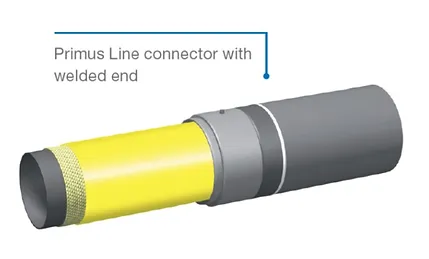

The R-Connectors by Primus Line Consist of a core and a bushing.

With R-Connectors, the core is first fitted into the bushing with an anti-friction agent. The busing has a malleable steel jacket inside that is pushed onto the liner and into an indentation on the core by a two-component resin. The result is a pull-proof unit of liner and connector.

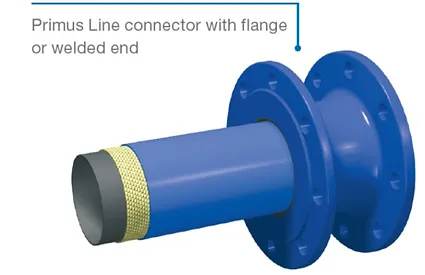

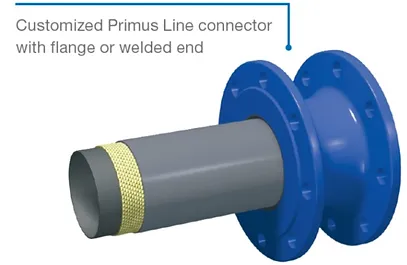

A leak-free pull-proof connection with the host pipe can be established with a flange or welding solution.

Benefits

Minor installation footprint

Minimum use of equipment

Decreased impact on traffic

Installation speeds of up to 10 metres per minute

Up to 2,500 Metres per pull

Quick re-commissioning for a minimal time of service interruption

Low pre-investment for installers

Installation through multiple bends of up to 45°

Withstands thermal expansion of the host pipe & seismic movement

Fully flexible seamlessly woven Kevlar Fabric®

Small pits & reduction of road work

Reduced use of machinery

Decreased impact on traffic

Minimal disturbance of daily life

100% Quality control during the manufacturing process

No curing, steaming or adhesion process

Independent of weather conditions during installation

50+/- Years lifetime

Overview

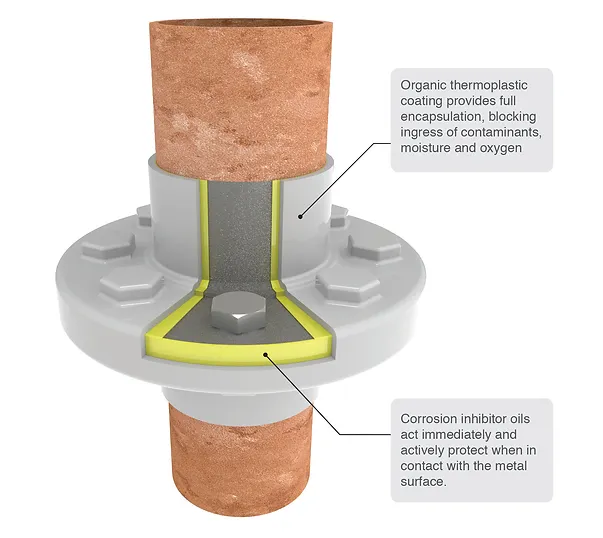

We are the sole distributor for Oxifree TM198 in Singapore. Oxifree TM198 is an organic thermoplastic coating for the protection of metallic components with complex geometries from corrosion.

OxiFree TM198

TM198 is melted down from a solid resin (in the supply unit) and applied using a heated hose and gun. It provides a pliable thermoplastic barrier coating, which will protect all types of metal components against galvanic pitting and atmospheric corrosion as well as protects your assets from water and dust ingress. It is ideal for flanges and valves on process piping and long term storage of equipment in normal atmospheric conditions. The material can easily be cut and removed for access and maintenance, the area of removed material can then be refilled as the newly applied material that will bond to the existing TM198 coating. The protected substrate can be inspected via UT directly through the material. There is no downtime during application and protection is provided immediately, bringing savings to both CapEx and OpEx. TM198 is proven to extend the life cycle of components and reduce maintenance costs. The core application machines have undergone extensive development and testing and come in 2 different tank sizes: 12lbs/5.5kg and 50lbs/22kg to cater for a wide range of application requirements. The larger machine is IECEx certified.

Industries

Oil & Gas

Petro - Chemical

Refinery

Power Generation

Nuclear Power

Pulp & Paper

Metal

Suitable Applications

Bearing Housing

Actuators

Electrical Conductors

Flange Assemblies

Graylock Clamp

Pipe Support

Pumps

Valves

Wellhead

Benefits

Savings to Both Operational & Capital Expenditure

Arrests All Types of Corrosion & Contamination

Applicable on Rotating Parts

Applicable on Sweating Pipes

Applicable on Live Assets

100% Reusable

Minimum Surface Preparation

No Solvents Content

Excellent UV Resistance

Complimentary to Other Coating Systems

Complimentary to NDT Inspection

Simple to Remove Without Damaging Substrate

Available in Various Colours

Encapsulates Substrate

Does Not Adhere to Structure

Fast to Apply & Cools Within 2 Minutes

Over 10 Years of Lifespan

Preserve Stored Assemblies

Application to Complex Geometry Areas

Certifications

ASTM B117 – Salt Spray Test

ASTM G154 – UV/Weathering Test

ASTM G85-94 – Annex A5 Prohesion Test

ASTM D790 – Cryogenic Bend Flexibility

ASTM E968 – Sand Abrasion Resistance

BS 3900-F2 – Cyclic Condensation

Boeing BSS 7239 – Smoke Toxicity Test

ASTM E662 – Smoke Generation Test

BS EN 13823 – Single Burning Item Test

UL 94 V2 – Flammability of Plastic Materials

ASTM D149 – Dielectric Strength Testing

BS2782 Pt.2 – Volumetric Resistivity Testing

GOL492/09 – Volatile Organic Compound Test

ASTM D7359/13 – Standard Test Method for Total Fluorine, Chlorine and Sulfur in Aromatic Hydrocarbons

overview

We are the sole distributor for STB Mechanical seals in South East Asia (SEA). STB designs and manufactures mechanical seals and special seals for gas and steam turbines, compressors (especially rotating piston, screw-, centrifugal compressors), pumps, mixers and agitators and many other applications where fluids, gases or steam need to be sealed.

Industries

Oil & Gas

Chemical

Water & Waste Water

Pharma-ceutical

Pulp & Paper

Metal

Auto-motive

Food & Beverage

Benefits

Short Lead Time

Customized to Size Shape & Standards

Design to Replace Existing OEM Seals

Cost Effective Solution

Easy Maintenance

API 682 Compliant

FDA Compliant

Long Product Life Span

Mechanical Seals

Cartridge SEals

STB designs and manufactures various mechanical cartridge seals. Its state-of-the-art manufacturing technology and short lead time for customised seals are some of the key benefits. Seals are customised based on application, dimension, and materials.

Single Cartridge Seals

Single mechanical cartridge seals are an extension and improvement of single component seals. Designed with shaft sleeves, to protect the shaft from damage. Most types are designed with integrated flushes, which are ideal for high viscosity products or products with a high amount of solid particles.

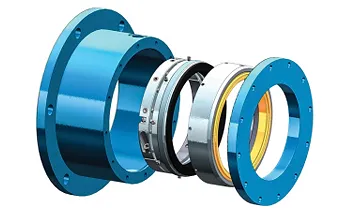

Double Cartridge seals

Double mechanical cartridge seals have a barrier or buffer fluid between both pairs of seal faces. One pair is located on the product side, the other pair is located on the atmospheric side. Between them is the barrier fluid to cool the seal faces and to ensure that no contamination of the environment will occur.

Siron Seals

Siron is a cartridge mechanical seal design available in single and double acting arrangements. It offers industry-leading consistent quality, standard and high availability. The cartridge design guarantees an easy installation of rotating equipment by eliminating installation mistakes.

OEM-Replacement seals

STB offers product-specific OEM-Replacement seals. STB provides mechanical seals for equipment such as: turbines, pumps, compressors and blowers. STB pays great attention to delivering the highest quality from design to delivery. Their automated production processes allow STB to have high availability and fast reaction times.

Replacement Seals for the following OEM systems:

Blackmer Pumps

Plunger Pumps

Screw Spindle Pumps

Sulzer Agitators

Slurry Pumps

agitator seals

Agitator seals have been used in large-scale industries for many years for sealing critical and dangerous media. The reliable sealing process plays a significant role for the environment and machinery operators. Agitator seals manufactured by STB GmbH meet the highest standards when it comes to their sealing function, lifespan and maintenance requirements. STB’s standard series are always readily available and at short delivery times.

component seals

Component mechanical seals are the simplest design of mechanical seals and are commonly used as a better alternative to dynamical packing systems. The design of a single component mechanical seal can include the following components: stationary seal face, dynamical seal face, springs, O-rings and steel parts. The construction in length, pressure resistance, and diameter can vary. STB also develops and manufactures special seals based on customer requirements.

Marine Seals

STB water-lubricated propeller shaft seal is an ecological and economical solution that meets all technical needs of a modern mechanical navy seal. Among others, it has a modular setup, is easy to assemble, requires low maintenance efforts and has no configuration. Propeller shaft seals use the same function principle as mechanical seals. Therefore, they are virtually leak-free and leave no oil or grease residue in the waterway.

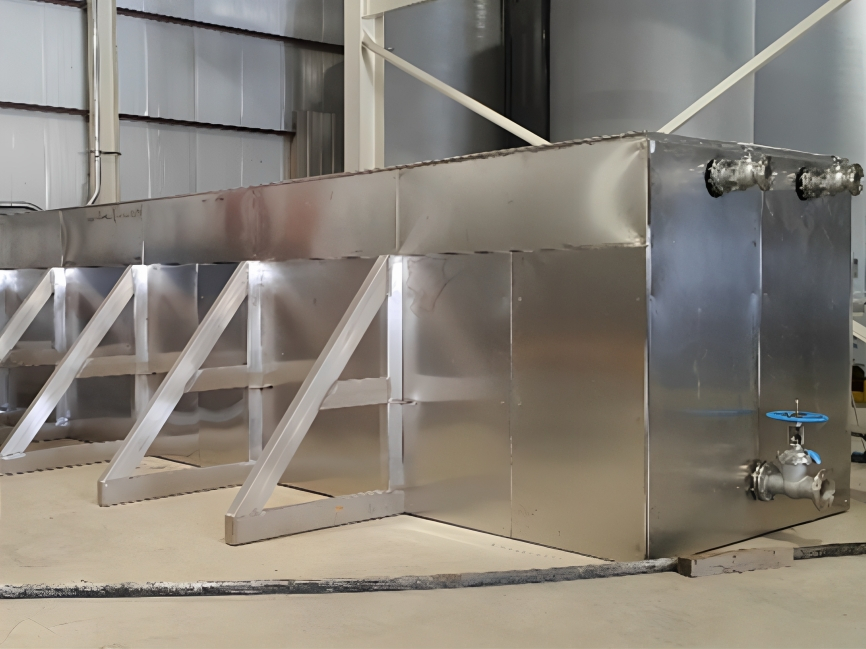

Mechanical Seal Support System

With the massive global expansion of double mechanical seals in the petrochemical, pharmaceutical and process industry, support systems are a necessary solution. Mechanical Seal Support Systems (MSSS) are able to extend the lifetime of a double-acting mechanical seal and increase the equipment’s safety massively.

Carbon Seals

STB manufactures carbon rings upon receipt of samples, drafts or by STB design based on your application. Due to high stocks of raw materials. STB offers the shortest lead time.

Carbon Seals

STB offers various mechanical packing solutions such as:

Tartarus Seal Kit – used in Plunger Pumps

Static Packing – used in Valves

Dynamic Packing – used in Pumps, Refiners and Mixers

Graphite Seal Packing – Graphite Seals, Packing System

Injection Packing – A Service and maintain friendly packing system

High-Pressure Packing – 700°C and 150 bar

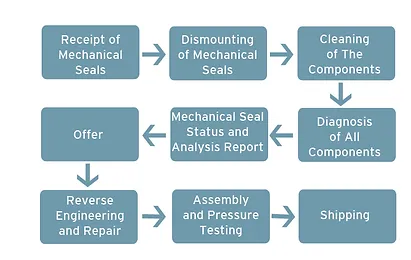

STB Services & Refurbishment

Our qualified engineers and service technicians work closely with the engineers at STB to apply their skills toward continuing the German tradition of high quality and reliability. STB provides overhauls to mechanical seals from all manufacturers.

The variants of mechanical seals include:

Component Seals

Cartridge Seals

Agitator Seals

Steam Head Gasket

Carbon Floating Seals

Enameled GLRD ATEX Seals

Dry Gas Seals

Customised Seals

Benefits of Stb Repairs

High-Quality Inspection, Overhaul & Modification

Flexible & Fast Processing of Orders

Done by Specially Trained Engineers for Mechanical Seals & Supply System

Professional & Environmentally Friendly disposal by Logistic Department Damage

Report Involving The Entire Assembly Unit, (if present) Supply System & All Components

High Flexibility Through Collaboration of Service & Production

Extensive Report for Further Decision-Making Purposes