Oxifree

Overview

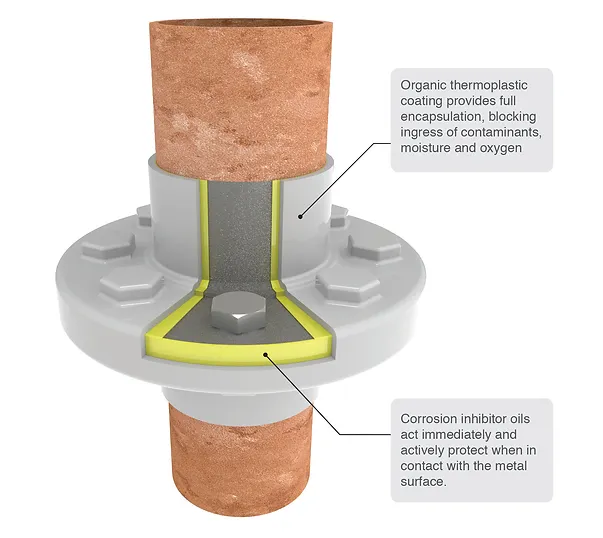

We are the sole distributor for Oxifree TM198 in Singapore. Oxifree TM198 is an organic thermoplastic coating for the protection of metallic components with complex geometries from corrosion.

OxiFree TM198

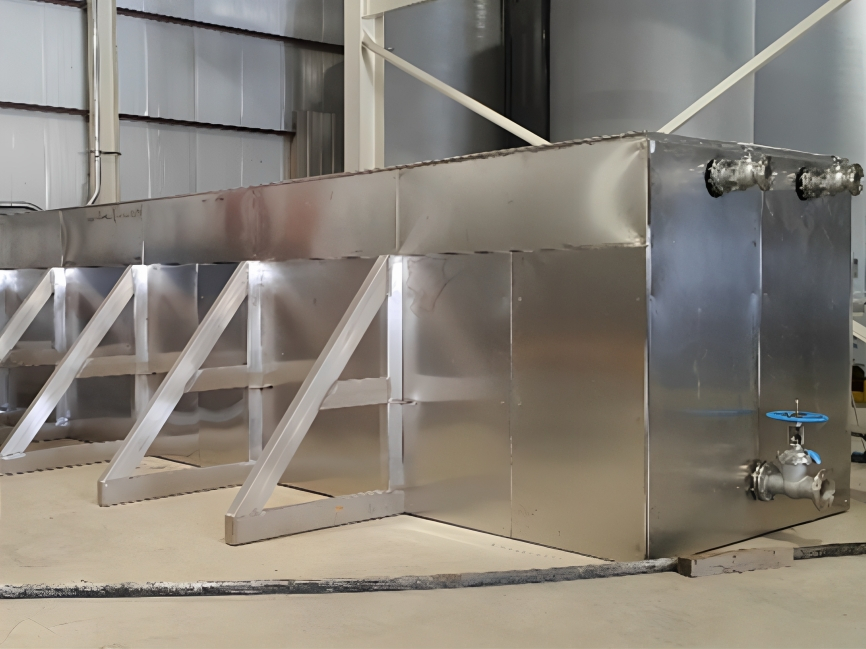

TM198 is melted down from a solid resin (in the supply unit) and applied using a heated hose and gun. It provides a pliable thermoplastic barrier coating, which will protect all types of metal components against galvanic pitting and atmospheric corrosion as well as protects your assets from water and dust ingress. It is ideal for flanges and valves on process piping and long term storage of equipment in normal atmospheric conditions. The material can easily be cut and removed for access and maintenance, the area of removed material can then be refilled as the newly applied material that will bond to the existing TM198 coating. The protected substrate can be inspected via UT directly through the material. There is no downtime during application and protection is provided immediately, bringing savings to both CapEx and OpEx. TM198 is proven to extend the life cycle of components and reduce maintenance costs. The core application machines have undergone extensive development and testing and come in 2 different tank sizes: 12lbs/5.5kg and 50lbs/22kg to cater for a wide range of application requirements. The larger machine is IECEx certified.

Industries

Oil & Gas

Petro - Chemical

Refinery

Power Generation

Nuclear Power

Pulp & Paper

Metal

Suitable Applications

Bearing Housing

Actuators

Electrical Conductors

Flange Assemblies

Graylock Clamp

Pipe Support

Pumps

Valves

Wellhead

Benefits

Savings to Both Operational & Capital Expenditure

Arrests All Types of Corrosion & Contamination

Applicable on Rotating Parts

Applicable on Sweating Pipes

Applicable on Live Assets

100% Reusable

Minimum Surface Preparation

No Solvents Content

Excellent UV Resistance

Complimentary to Other Coating Systems

Complimentary to NDT Inspection

Simple to Remove Without Damaging Substrate

Available in Various Colours

Encapsulates Substrate

Does Not Adhere to Structure

Fast to Apply & Cools Within 2 Minutes

Over 10 Years of Lifespan

Preserve Stored Assemblies

Application to Complex Geometry Areas

Certifications

ASTM B117 – Salt Spray Test

ASTM G154 – UV/Weathering Test

ASTM G85-94 – Annex A5 Prohesion Test

ASTM D790 – Cryogenic Bend Flexibility

ASTM E968 – Sand Abrasion Resistance

BS 3900-F2 – Cyclic Condensation

Boeing BSS 7239 – Smoke Toxicity Test

ASTM E662 – Smoke Generation Test

BS EN 13823 – Single Burning Item Test

UL 94 V2 – Flammability of Plastic Materials

ASTM D149 – Dielectric Strength Testing

BS2782 Pt.2 – Volumetric Resistivity Testing

GOL492/09 – Volatile Organic Compound Test

ASTM D7359/13 – Standard Test Method for Total Fluorine, Chlorine and Sulfur in Aromatic Hydrocarbons