Updated: Dec 24, 2018

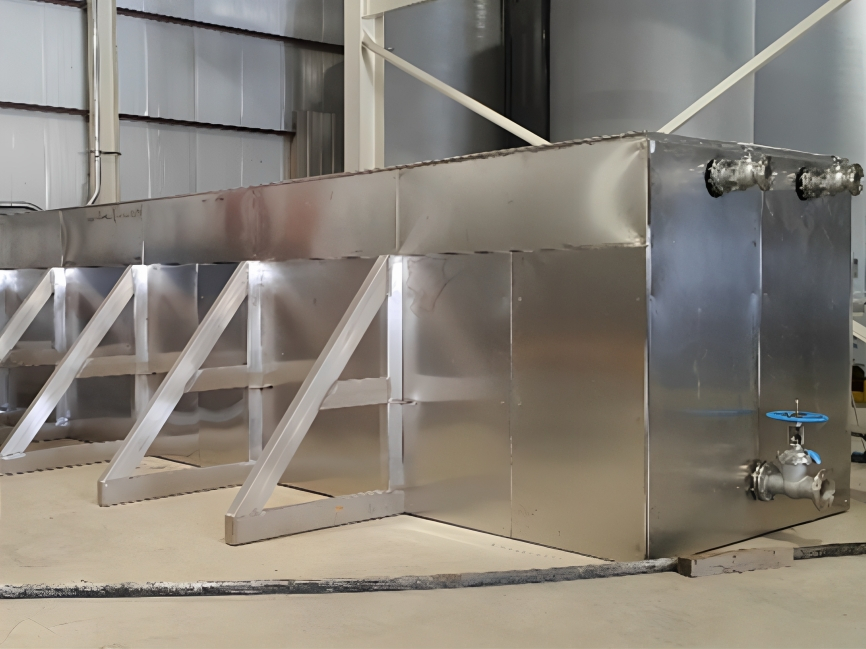

Our shell side Bundle Blaster system offers a powerful and automated solution for external cleaning of heat exchangers and tube bundles. The Bundle Blaster is safer and more effective than traditional hand-held methods of shell side cleaning. This machine is fully automated and only requires one operator.