Primus Line

overview

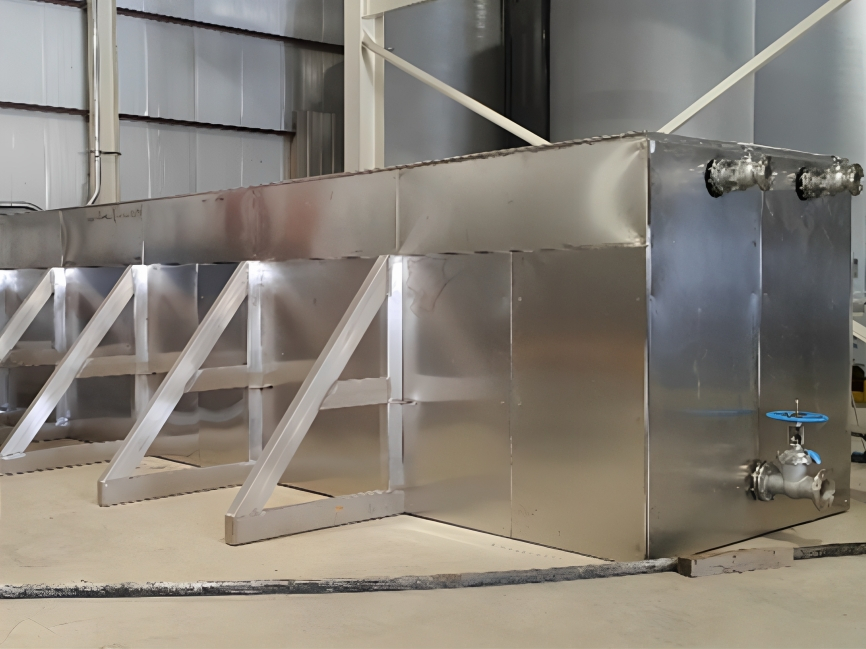

We are an authorised Prime Installer for Primus Line® in Singapore. Primus Line® is an innovative technology for the trenchless rehabilitation of pressure pipelines for different media such as oil, water and gas.

The Prime Solutions for Pipes

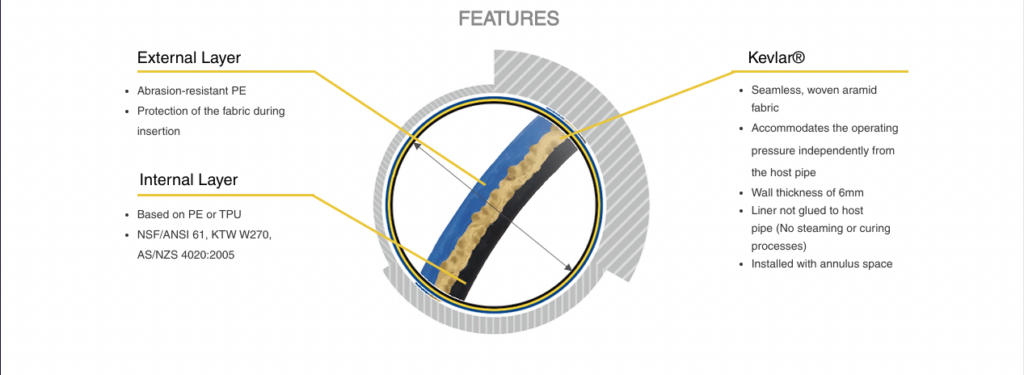

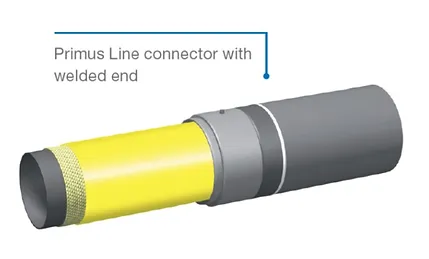

The system consists of a Flexible Kevlar® reinforced liner and specially developed end fittings. Primus Line® is not bonded to the host pipe.

Suitable Applications

The industry is facing new challenges as a result of damage to steel pipelines caused by internal corrosion. Possible leakages might cause significant environmental damage; they also mean increased costs or even loss of reputation for network operators.

Primius Line

Water

Primus Line® is suitable for the transportation of various liquids in the field of water and holds drinking water approvals in numerous countries. The ideal flow characteristics caused by an extremely smooth inner coating and optimised systems for high, medium, and low-pressure requirements make Primus Line® an economical solution for the rehabilitation of ageing pipelines. Thus, water authorities and network operators benefit from the reliable operation and sustainable investment in their fixed assets. Potable Water, Firefighting Water, Industrial Water, Sea Water, Waste Water

Primius Line

Oil

Primus Line® is suitable for the renovation of oil pipelines due to the medium-specific inner layer and acts as a corrosion barrier between the transported fluid and host pipe. The conveyed fluid covers media from the categories such as crude oils, fuel oils, oil slag and other refined products. Gathering Pipelines, Transmission Lines , Jetty Pipelines, Process Water Mains, Fire Fighting Mains. Please get in touch with us for our Chemical Resistance sheet to know more.

Primius Line

Gas

Gaseous media represents a special challenge to trenchless pipeline rehabilitation. However, an inner layer made of permeation reducing plastics and the seamless production of up to 4,500 metres (14,763 feet) of the Primus Line® pipe has made it possible for gas pipelines to also be renovated with Primus Line®. A monitoring pipe with a fitted valve that is affixed to the old pipeline allows the system-specific annular space to be monitored after the renovation work. Natural Gas Core Gas Liquid Gas Mixed Gas. Please get in touch with us for our Chemical Resistance sheet to know more.

Installation

1. INSTALLATION OF THE LINER

Assembly of the pulling head

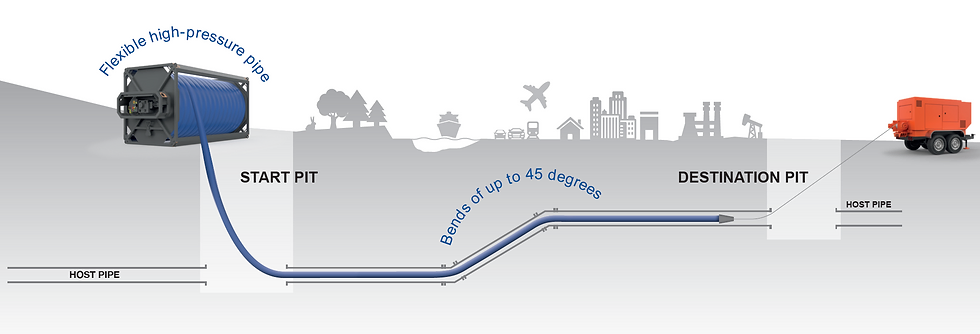

Before installation, the liner is fitted with a pulling head that is designed for forces of up to 100 kN. A swivel in the pulling connection with the winches prevents the liner from twisting on its way from the start to end pit.

Installation

The liner is delivered folded. That way Primus Line® can be installed even in pipes with the same nominal diameter.

Adhesive tape keeps the liner in this U-shape until it is pressurised with about 500 mbar. Subsequently, it assumes its round form.

2. ASSEMBLY OF THE CONNECTORS

Assembly of the M-Connector

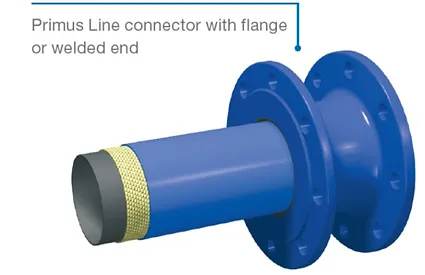

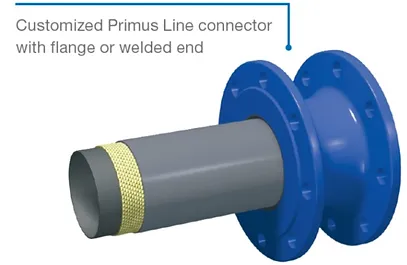

The M-Connectors by Primus Line consist of a bushing and a core. With the M-Connector, a pull-proof unit out of the liner and connector is established by hydraulically pressing the core into the bushing.

Screwed to a flange on the host pipe a leak-free pull-proof connection is established that forms a closed annulus.

Assembly of the R-Connector

The R-Connectors by Primus Line Consist of a core and a bushing.

With R-Connectors, the core is first fitted into the bushing with an anti-friction agent. The busing has a malleable steel jacket inside that is pushed onto the liner and into an indentation on the core by a two-component resin. The result is a pull-proof unit of liner and connector.

A leak-free pull-proof connection with the host pipe can be established with a flange or welding solution.

Benefits

Minor installation footprint

Minimum use of equipment

Decreased impact on traffic

Installation speeds of up to 10 metres per minute

Up to 2,500 Metres per pull

Quick re-commissioning for a minimal time of service interruption

Low pre-investment for installers

Installation through multiple bends of up to 45°

Withstands thermal expansion of the host pipe & seismic movement

Fully flexible seamlessly woven Kevlar Fabric®

Small pits & reduction of road work

Reduced use of machinery

Decreased impact on traffic

Minimal disturbance of daily life

100% Quality control during the manufacturing process

No curing, steaming or adhesion process

Independent of weather conditions during installation

50+/- Years lifetime